- トップページ/

- ZUTTOのよみもの/

- ブランドストーリー/

- WAJIMA KIRIMOTO -...

WAJIMA KIRIMOTO - Modern Wajma-nuri, Urushi Lacuqerware from Wajima CIty

Wajima City, Ishikawa Prefecture, is one of the well-known areas for the production of Urushi lacquerware. Urushi is a natural lacquer taken from urushi tree and widely used in Japan and other Asian countries. Urushi lacquerware produced in Wajima City is called Wajima-nuri that has durable multilayered urushi coating.

Urushi is applied to wood products because it enhances durability and protects them from damage. Usually, urushi lacquerware has a glossy texture that makes itself look nice.

Here is a coffee cup that WAJIMA KIRIMOTO produces. The material is wood but by having urushi coating on, it makes us easy to drink coffee smoothly and preserves itself from damage.

This soup spoon is also made of natural wood with urushi lacquer. When you serve the spoon to your mouth, you may be surprised how gentle the touch of the spoon is. The spoon is also lightweight and easy to use.

WAJIMA KIRMOTO's woodwork and urushi

Usually, Wajma-nuri is made by multiple different craftmen. Each craftman is professional in different processes, such as producing and promotion, woodwork, painting, and polishing products.

The featured brand WAJIMA KIRIMOTO originally started the family-owned company that is specialized in carving wood for the base of Wajima-nuri for more than 200 years. In 2015, it changed the name to WAJIMA KIRIMOTO and started producing wooden and urushi lacquerware that would fit our modern lifestyles.

As a professional of wood, the brand explores to make good use of natural woods and endeavors well-designed products that could be effectively used in everyday life.

Woods for KIRIMOTO's products

WAJIMA KIRIMOTO prefers using the magnolia tree for the material. Magnolia tree is stable and easy to be carved. Therefore, KIRIMOTO makes products with the material that has a smooth curve. Also, urushi lacquer soaks well in the wood, and works excellently as a coating.

Cypress is also a standard woods for the products. It is another stable wood that has been used for old shrines in Japan. Cypress has fine wood grains and goes well with urushi lacquer.

Techniques of KIRIMOTO's urushi lacquerware

As we say urushi lacquerware, there are some differences between each other, especially in the ways of the coating. WAJIMA KIRIMOTO chooses multiple techniques for each product. You would find differences in the texture and look.

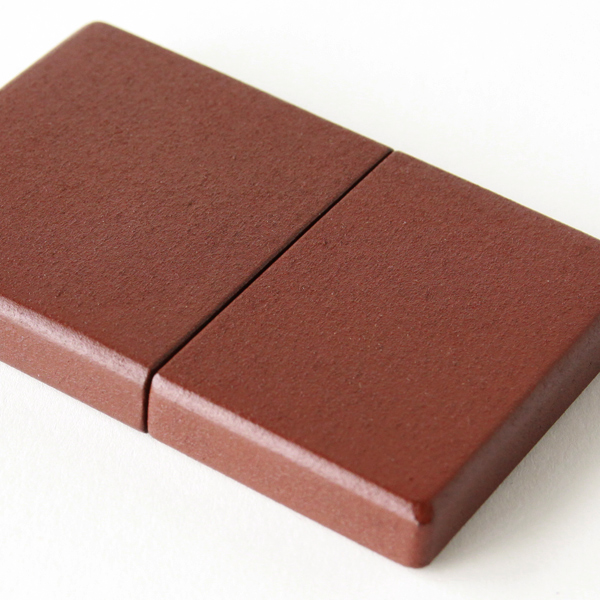

Fuki-urushi

Fuki-urushi is one of the major techniques of urushi coating. Raw urushi is applied to a product directly, then is wiped out with a cloth. Artisans repeat the process about 3-5 times and rub urushi in a product. By doing so, urushi well soaks in the wood, and the wood gains strength while presenting wood grain beautifully.

Honkataji

The glossy urushi lacquerware is made with a multi-layer of urushi and base coat. To be accurate, Honkataji is not the way of urushi coating, but it is a way for the base. WAJIMA KIRIMOTO uses diatomaceous earth collected from Mt. Komine in Wajima City and make it into a powder by firing up. The powder is called Wajima jinko that would be applied to a product. It becomes the base for the product, and artisans polish and apply multiple urushi coatings on it. This process takes time, but the product becomes sturdy and long-lasting.

Makiji

Makiji is different from Honkataji because Wajima jinko, the powder used for the base in Honkataji, would be applied on the surface of a product. After applying urushi lacquer on a product, artisans place Wajima jinko at last. The texture of the Makiji product looks rougher than a Honkataji product.

All the products from WAJIMA KIRIMOTO could be used in our daily lives. Urushi and the highly-skilled woodwork make them useful and long-lasting.

Click here to see more WAJIMA KIRIMOTO urushi products

.jpg)

.jpg)

.jpg)

.jpg)